Long Stroke Pumping Units

Forland Services has developed a new generation of long stroke pumping units that include a bi-directional motor and integrated control system. The units also feature a planetary gear box and open-looped chain/travelling sprocket transmission system, inner-tower counterweight system and a flexible load belt. The control cabinet includes an integrated power supply, VFD, PLC unit, human machine interface (HMI) module, physical indicators/buttons, and an optional remote access module.

The Forland long-stroke pumping unit can achieve independent upward and downward stroke speeds. This is beneficial especially for heavy oil wells, horizontal wells and wells that are prone to gas lock. Additionally, stroke lengths are automatically adjusted and the working region of the stroke can be customized with no sacrifice to production capacity.

Besides slower operating speeds, which lead to fewer pump cycles and increased pump life, the unique selectable stroke section and independent controllable upward/downward speed makes the Forland unit highly efficient. It is able to solve complicated issues in high deviation, high fluid volume, high water-cut, and heavy oil conditions where other forms of lift tend to cause excessive down time.

In many applications, these units can eliminate the use of initial mid-sized ESPs and/or assist in transitioning from ESPs or from gas lift to rod lift sooner. For vertical wells where initial production is in the 700 to 900 bpd range, the Forland long-stroke unit is also efficient and can be installed during the first stage of lift, enabling consistent downhole equipment through the life of the well.

Specific Features

- Configurable upper and lower part of stroke length setting allows to use various stroke length and stroke interval (e.g. upper part recommended for API RHI and RWT travelling barrel pumps, and lower part recommended for others). (See video)

- Automatic SPM adjustment based on diagnosis of dynanometer card; independent up stroke and down stroke speed contol, improving pump volumetric efficiency and helping eliminate gas-lock problems. (See video)

- Broad range of polish-rod load from 3 tons to 30 tons and fluid volume up to 7000 bpd meets a variety of production goals.

- Soft reversing mechanism (adjustable motor communication time) reduces impact on rods and downhole pump and improves system life span.

- Intelligent control system includes an integrated power supply, VFD, PLC unit, HMI module, physical indicators/buttons, and optional remote access module.

- Smart dual-traveling sprocket structure avoids the use of carriage as traversing mechanism and markedly reduces required torque to allow the use of smaller motor and gear reducer.

- Linear counter balance and low system disturbance make dynamometer card run very close to a theoretically perfect card.

- Easy counterweights change and ECB adjustment.

- 90% pre-assembled for easier onsite installation; easy well service with no heavy equipment required; easy on-site repair of most major components.

- Motors reduce energy consumption typically 30%.

- Multiple safety features including most moving parts enclosed within the structural tower away from personnel.

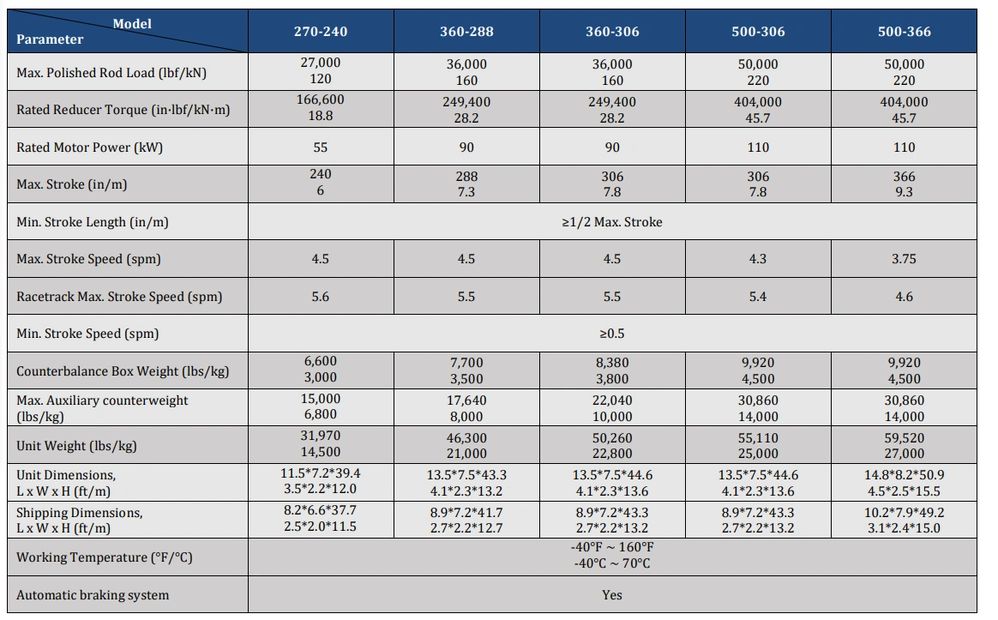

SPECIFICATIONS

Maximum Production

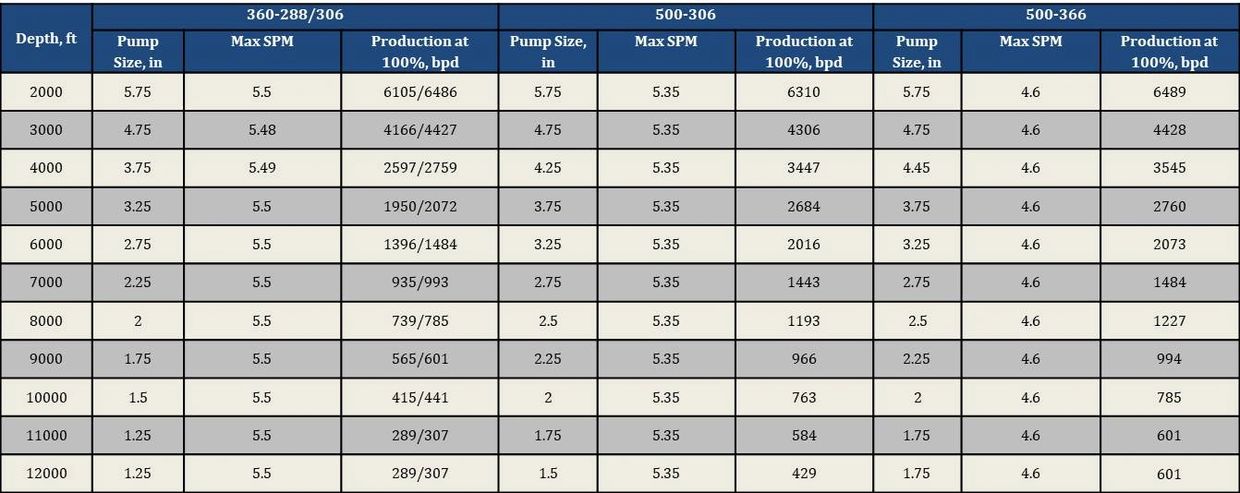

Maximum Production by Depth